Addressing the root cause of air leakage issues

Improvements provide energy efficiency and comfort for clinic in Woodstock, Ontario

When staff at Woodstock Rehabilitation Clinic noticed icy floors and frigid temperatures in one corner of their building, Woodstock General Hospital partnered with BELi Labs Inc. to address air leakage issues.

Air infiltration was not only increasing the building’s heating load and energy costs, but also raising safety concerns around potential moisture damage and mould growth in the clinic.

Highlights

- Woodstock General Hospital partnered with BELi Labs Inc. to address air leakage at Woodstock Rehabilitation Clinic, reducing heating costs and mitigating risks of moisture damage and mould growth.

- Through Enbridge Gas Commercial Airtightness Testing Program, the clinic not only achieved a tighter building envelope but also resolved hidden structural issues like thermal bridging, enhancing long-term comfort and durability.

By the numbers*

26,069 sq. ft.

building with 2 storeys

11%

Reduction in air infiltration

$34,000

Enbridge Gas incentives

Financial support from diagnosis to treatment

“When it comes to air leakage issues in an operating building, sometimes they can travel a very complicated path,” said Randy Van Straaten, president of BELi Labs Inc. “And when you have a busy clinic that’s vital to the community and can’t shut down that readily, that’s an even larger challenge.”

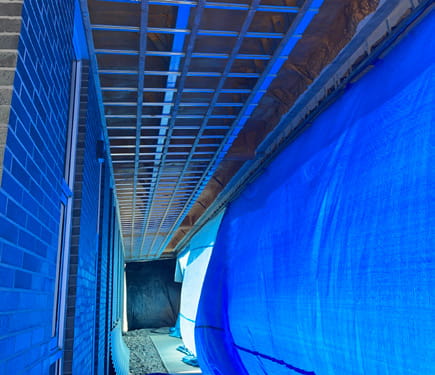

After a series of blower door and smoke tests using a pressure-assisted fog machine to highlight problem areas, BELi Labs Inc. implemented a targeted approach to air sealing on the affected corner of the building. The clinic received incentives from the Enbridge Gas Commercial Airtightness Testing program for both for the initial assessment and envelope improvements.

“The comments I got from occupants were all about comfort. The rooms felt much warmer, especially in the winter.”

Chris Marion

Director of Capital Projects

Woodstock General Hospital

A healthier building for years to come

In addition to improving comfort for doctors, patients and staff, the air sealing tests helped the team identify and address thermal bridging issues within the structure of the building.

“We didn’t just get a tighter building envelope—we solved a few other problems at the same time,” said Chris Marion, director of capital projects at Woodstock General Hospital. “That was a nice surprise.”