Industrial Custom Engineering

How the world’s first major carbon-neutral food company keeps saving

Maple Leaf Foods is a leading North American producer of value-added meat and plant protein products. In 2019, it became the first major food company in the world to be carbon neutral, and set an absolute science-based target to cut its greenhouse gas emissions by 30 percent by 2030. To achieve this, facilities like the Heritage plant in Hamilton, Ontario must find innovative strategies to reduce emissions, with expertise, technical support and incentives from Enbridge Gas.

Highlights

-

A heat recovery project was implemented by Maple Leaf Food, and the Industrial Custom Engineering program offered by Enbridge Gas covered close to 50 percent of the company’s investment.

-

The benefits add up:

1. Significant reduction of greenhouse gas (GHG) emissions.

2. Strengthening the company's culture of conservation.

3. More efficient use of heat that would otherwise be wasted.

Project highlights

$10,000

incentive for plant-wide energy audit

$2,750

for engineering feasibility study

$104,000

Enbridge Gas incentive

$160,000

saved annually

850,000 m3

natural gas saved annually

1,500 tonnes

of CO2e eliminated

A strong partnership drove a successful heat recovery project

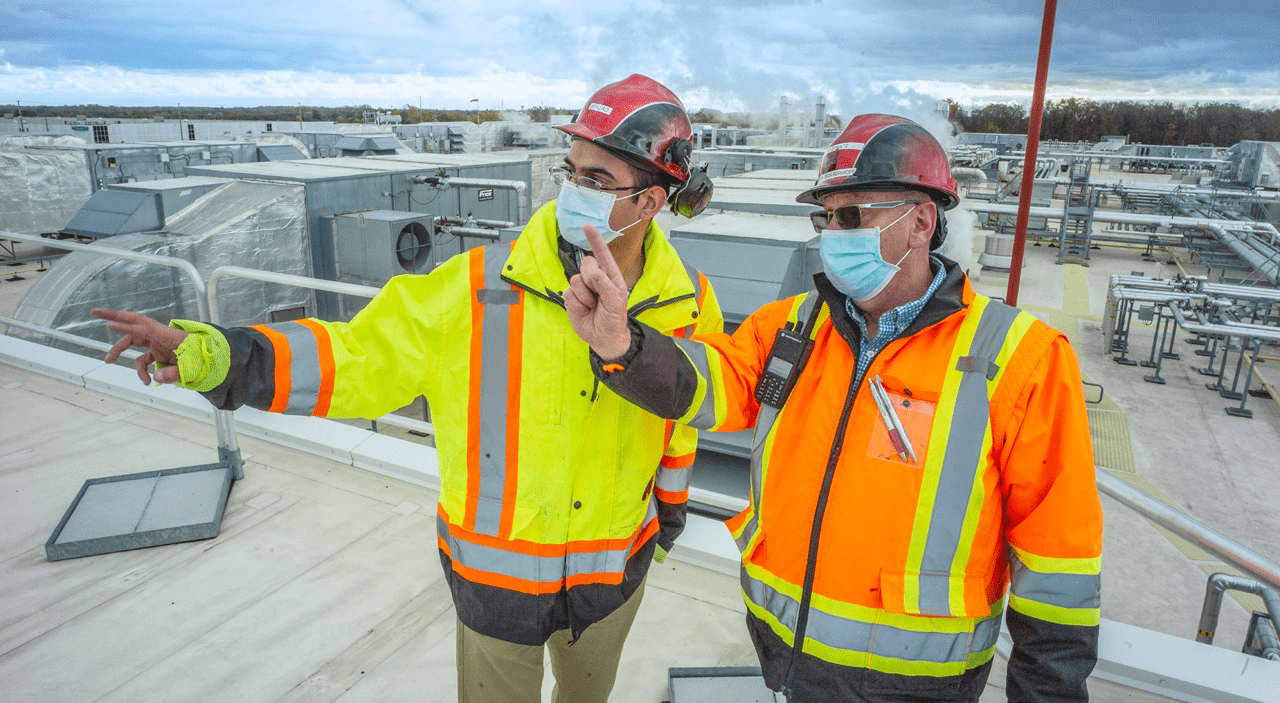

Food production can be extremely energy-intensive. For Maple Leaf Foods’ Mike Schultz (Director, Technical Services), Serguei Taran (Chief Operating Engineer) and Behzad Hosseinpour (Manager of Energy and Sustainability), finding any efficiencies in the plant’s operations would contribute to corporate sustainability goals while also reducing energy costs.

In 2015, with the support of Enbridge Gas, a plant-wide energy audit uncovered a variety of energy-saving opportunities—some quick wins and others that required deeper investment and analysis. Schultz was particularly interested in a heat recovery project that would capture and reuse heat generated from the facility’s ammonia refrigeration system. He turned to Enbridge Gas Energy Solutions Advisor, Jordan Meunier, for support to help strengthen the internal business case.

“Mike championed this project from the start,” said Meunier. “That’s what makes a strong partnership—if you don’t have a mindset of conservation, even money won’t help move a project forward.”

"Our relationship with Enbridge Gas was and remains instrumental to our projects. Incentives and guidance are available, even if you don’t know where to start.”

Behzad Hosseinpour, Manager of Energy and Sustainability,

Maple Leaf Foods

An incentive assurance letter strengthened the capital request

In 2018, Meunier helped facilitate an engineering feasibility study to more thoroughly assess the refrigeration heat recovery project. To help the team justify the investment, he also drafted an incentive assurance letter outlining the exact amount that Maple Leaf Foods would receive should the project be implemented.

“For any project, we need to demonstrate sustainability impact, cost savings and a return on net assets. Jordan guided us through the process and helped secure an incentive,” said Hosseinpour. “The assurance letter confirmed our payback period would be cut in half, and definitely had an impact on the decision-making process.”

The plant reduced natural gas intensity by 20 percent

The heat recovery project was implemented in 2020, and the Industrial Custom Engineering program covered close to 50 percent of the company’s investment. Today, the recovered waste heat is used to heat water, which keeps levels steady for sanitation processes, and reduces the plant’s natural gas intensity by 20 percent.

Beyond cost savings, reception has been overwhelmingly positive from operators—so successful, that other plants are now considering similar projects. Hosseinpour credits a strong partnership as key to success: “Involving Enbridge Gas years earlier allowed us to build their knowledge and incentive into our capital request. Any time they’re involved, our financial case is stronger.”