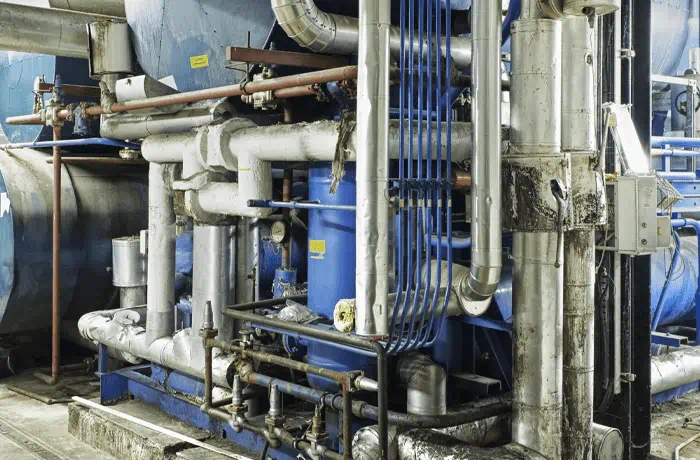

Reduce energy waste and costs through heat recovery

Did you know that roughly one-third of the energy consumed by industry is wasted as a result of inefficiencies? In industrial facilities or institutional buildings, heat recovery captures and repurposes wasted heat generated from equipment and processes and puts it towards something useful.

Save energy with incentives that pay up to 75 percent of incremental project costs for heat recovery projects.

Why upgrade?

-

Repurpose the heat you’re already paying for.

-

Improve process heating efficiency.

-

Reduce energy, maintenance and operating costs.

-

Improve workplace productivity.

-

Reduce greenhouse gas (GHG) emissions.